Industrial Pumps

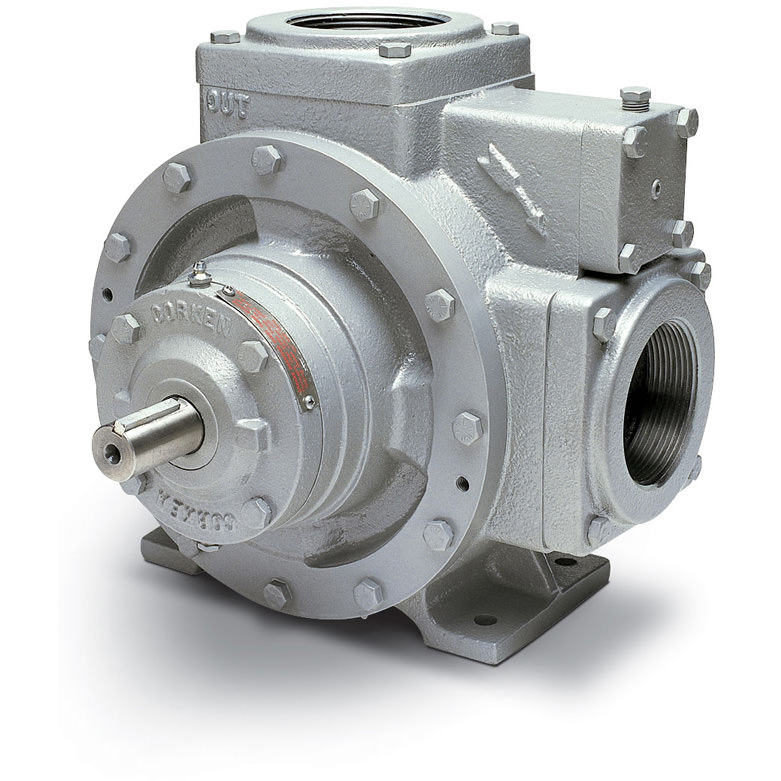

High Pressure Positive Displacement Sliding Vane Pump

2 in. Inlet/Outlet, 400 PSIG, 100 GPM MAX GPM, 950 MAX RPM

Only $3,780.40

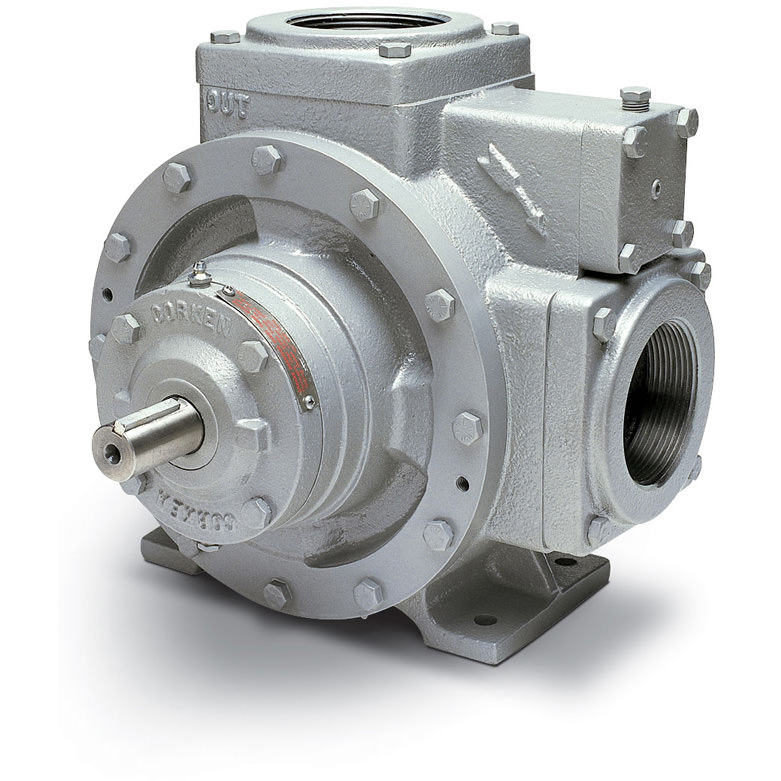

High Pressure Positive Displacement Sliding Vane Pump

3 in. NPT Inlet/Outlet, 400 PSI, 190 GPM MAX, 780 MAX RPM

Only $5,172.70

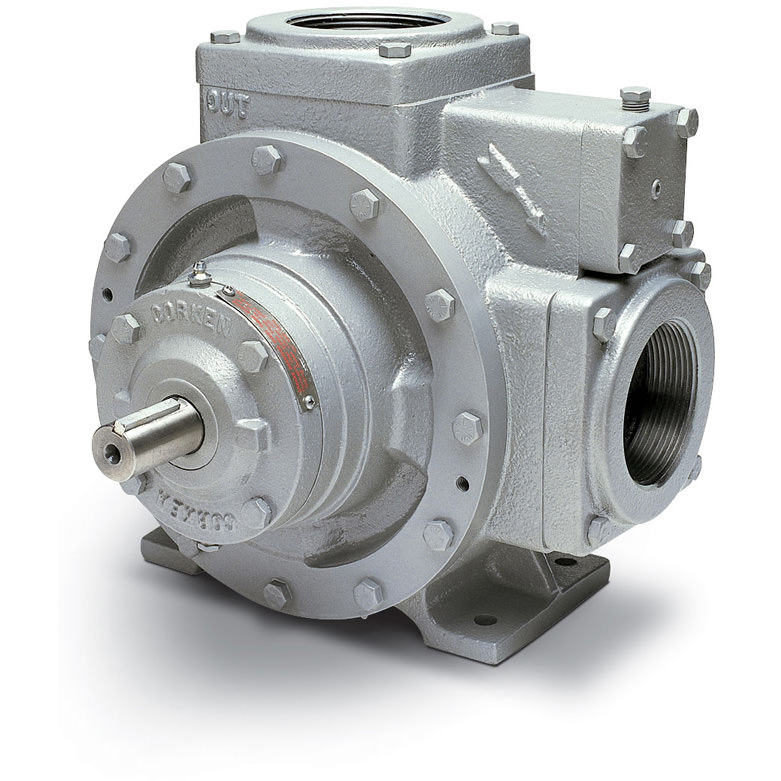

High Pressure Positive Displacement Sliding Vane Pump

4 in. NPT Inlet/Outlet, 400 PSIG, 400 GPM MAX, 780 MAX RPM

Only $7,459.40

Sliding Vane Pumps For LPG & Ammonia Applications

Corken?s positive displacement sliding vane pump, known as a Coro-Vane®, is an excellent choice for propane, butane, and agricultural ammonia applications.

Corken sliding vane pumps are used in a wide range of applications within the LPG, refined fuels and chemical industry. The sliding vane pump is a popular design for applications requiring flow rates of 20 GPM or more. The sliding vane design combines low cost with high reliability and easy maintenance.

The operating principle is simple. A slotted rotor is eccentrically supported in a cycloidal cam. The rotor is placed close to the wall of the cam so a crescent shaped cavity is formed. The rotor is sealed into the cam by two sideplates. The clearance between the rotor and sideplates is eight to ten thousandths of an inch depending on the model. Vanes, also known as blades, slide in and out of the rotor slots to seal off a volume between the rotor, cam and sideplate. Liquid enters the crescent shaped pumping chamber through holes in the cam. The blades sweep the fluid to the opposite side of the crescent where it is squeezed through the discharge holes of the cam as the blade approaches the point of the crescent.