*Image is a representation of this item. Actual item may vary.*

Hover over image to zoom

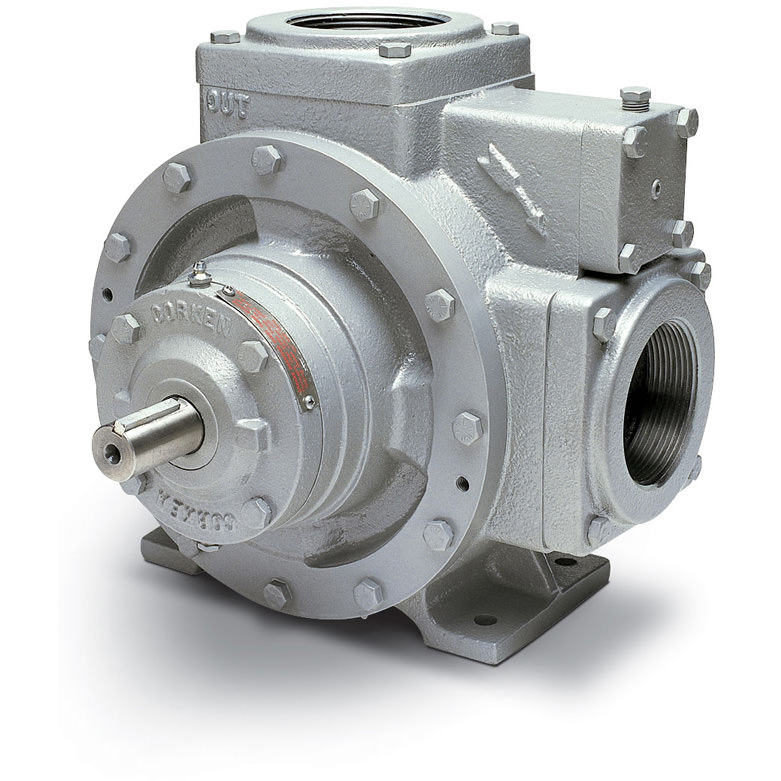

Corken CDBN1022 High Pressure Positive Displacement Sliding Vane Pump

3 in. NPT Inlet/Outlet, 400 PSI, 190 GPM MAX, 780 MAX RPM

Corken CDBN1022 High-Pressure Sliding Vane Pump

Manuals and Information:

CD-model sliding vane industrial pumps are designed for a maximum working pressure of 400 psi (27.6 bar). The sliding vane design has self-adjusting vanes that offers a consistent level of pumping efficiency throughout the life of the pump. They are constructed with a combination of gaskets and O-rings, have an adjustable internal relief valve, and a wide variety of mechanical sealing options. Ideal for petroleum products with low vapor pressures such as petroleum based oils, fuel oils and lube oils, and thin liquids such as alcohols and solvents.

Operating Specifications

- Flow rates up to 190 gpm (1,514 l/min)

- Working pressures up to 400 psi (27.6 bar)

- Differential pressures up to 125 psi (8.6 bar)

- Temperature range: -25 to 225 °F (-32 to 107 °C)

- Viscosities up to 20,000 SSU (4,250 cSt)

| Model | Inlet | Outlet | GPM | RPM | 50 PSI1 | 100 PSI1 | Maximum Differential Pressure | Maximum Working Pressure | Degrees °F2 | Approximate Shipping Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| CDBN1021 | 3 in. | 3 in. | 190 | 780 | 10 | 20 | 125 PSI | 400 PSIG | 225 | 160 lbs. |

1Motor Horsepower Required at Rated Speed Pumping 100 SSU Liquid

2Maximum Recommended Temperature for Catalogued Pump

Construction

| Model | Casing & Heads | Bearing Cap | Rotor | Shaft | Vane & Pushrods1 | Liner & End Plates | Rotating & Stationary Parts2 | O-Rings3 | Other O-Rings3 | Bearings (2 required) | Internal Relief Valve Spring |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CDBN | Ductile Iron | Iron | Ductile Iron | Steel | Composite | Iron | Carbon vs. Ni Resist | Buna-N | Buna-N | Anti-Friction Roller | Cadmium Plated Steel |

1Vanes are Ryton®, pushrods are glass filled Teflon®.

2All other seal parts are steel, optional stainless steel seat available.

3Optional elastomers for seal and O-rings are Viton®, Teflon®, Neoprene®, Ethylene Propylene and Kalrez.

Materials

- Pump casing and heads: Ductile iron

- Cam and sideplates: Gray iron

- Rotor and flanges: Ductile iron

- Seal seat: Stainless steel or Ni-resist

- O-rings: Buna-N, PTFE, Viton®, Neoprene®. Registered trademarks of DuPont

- Vanes: Advanced polymers

Features

- Self-adjusting sliding vanes maximizes performance

- Cam and sideplates can be replaced. Sideplates are reversible

- Maintenance is simple and cost effective: By simply removing the pump head, you can easily replace the internals without disturbing the piping

- Can handle small amounts of vapor so they are ideal for liquefied gases

- Excellent suction lift is great for clearing suction and discharge lines

- Adjustable internal relief valve

Liquids

- Aviation fuels

- Fuel oils

- Liquefied gases

- Lube oils

- Solvents

- And many more

Applications

- Terminal

- Bulk plant

- Truck and Transport

- Mobile (trailers & portable skid units)

| Model | A Inlet | B Outlet | C | C11 | D | D1 | D21 | E | F | G | H | J | K | L | M | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CDBN1021 | 3 in. | 3 in. | 7.06 IN. (179 MM) | 0 | 7.19 in. (183 mm) | 5.5 in (140 mm) | 0 | 2 in. (51 mm) | 1.75 in. (44 mm) | 4.12 in. (105 mm) | 5.38 in. (137 mm) | 8.5 in. (216 mm) | 6.5 in. (165 mm) | 11.25 in. (286 mm) | 5.25 in. (133 mm) | 9.88 in. (251 mm) |

1NOTE: For some models C1 and D2 will be 0. This denotes that the suction and/or discharge flange will be centered with the shaft.

Motor Options

| Model # | Enclosure | HP | RPM | Volts | Hertz | Phase | Weight |

|---|---|---|---|---|---|---|---|

| 6010-1C2B1 | Explosion Proof | 10 | 1800 | 230/460 | 60 | Three | 175 lbs. |

| 6010-1B2B1 | TEFC | 160 lbs. | |||||

| 6010-1D2B1 | Severe Duty TEFC | 160 lbs. | |||||

| 6010-1A2B1 | Open Drip Proof | 135 lbs. |

NOTE: Other Motor Options are available. Call us at 1-800-433-8831 to inquire additional models.

Mounting Options

| Part Number | Description | Max Driver Size (HP) |

|---|---|---|

| 101GRB- | Mounting set-up for Direct Drive Includes size "B" gear reducer, steel baseplate mounting, reducer bracket, couplings, and coupling guard. | 182T-254T |

| 103- | Mounting set-up for V-Belt Drive Includes steel baseplate mounting, adjustable motor slidebase, V-belt drive and enclosed beltguard. | 184T, 215T, or 256T |

No reviews yet!

Be the first to add a review.

*Reviews are subject to approval