*Image is a representation of this item. Actual item may vary.*

Hover over image to zoom

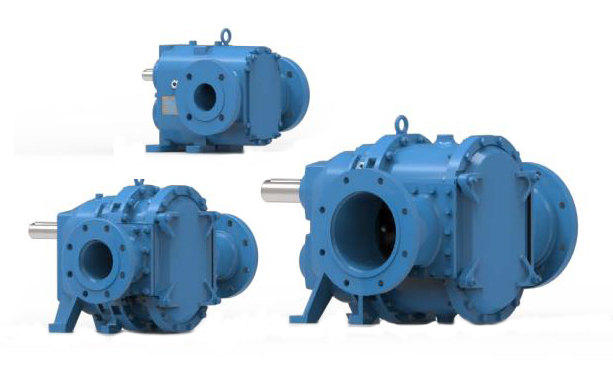

LobePro Rotary Pumps D Series Duplex Rotary Lobe Pump

72 - 2660 GPM, 50 - 175 PSI, 100-900 RPM

Ships From Manufacturer

Select Model & Quantity:

| Model # | Description | Price |

|---|---|---|

| DS8p | Proform Wet-end, 72 GPM, 175 PSI, 100-900 RPM | Call For Price |

| DS16p | Proform Wet-end, 144 GPM, 100 PSI, 100-900 RPM | Call For Price |

| DS8c | Component Wet-end, 72 GPM, 175 PSI, 100-900 RPM | Call For Price |

| DS16c | Component Wet-end, 144 GPM, 100 PSI, 100-900 RPM | Call For Price |

| DM34 | Overhanging Shafts, 204 GPM, 145 PSI, 100-600 RPM | Call For Price |

| DM50 | Overhanging Shafts, 300 GPM, 125 PSI, 100-600 RPM | Call For Price |

| DM68 | Overhanging Shafts, 408 GPM, 100 PSI, 100-600 RPM | Call For Price |

| DM100 | Overhanging Shafts, 600 GPM, 50 PSI, 100-600 RPM | Call For Price |

| DL133 | Overhanging Shafts, 665 GPM, 125 PSI, 100-500 RPM | Call For Price |

| DL133h | Fully Supported Shafts, 665 GPM, 175 PSI, 100-500 RPM | Call For Price |

| DL266 | Overhanging Shafts, 1330 GPM, 75 PSI, 100-500 RPM | Call For Price |

| DL266h | Fully Supported Shafts, 1330 GPM, 150 PSI, 100-500 RPM | Call For Price |

| DL399 | Overhanging Shafts, 1995 GPM, 40 PSI, 100-500 RPM | Call For Price |

| DL399h | Fully Supported Shafts, 1995 GPM, 85 PSI, 100-500 RPM | Call For Price |

| DL531h | Fully Supported Shafts, 2660 GPM, 70 PSI, 100-500 RPM | Call For Price |

LobePro Rotary Pumps - D Series - Duplex Rotary Lobe Pump

Manuals and Information:

All LobePro CD3mn parts are solution annealed and passivated. This is very important to obtaining the best resistance to chloride corrosion, pitting and cracking.

Principle reason to use LobePros D Series for these applications includes:

- Reversable (can load, unload and backwash)

- Strong vacuum/Self-priming to 25 feet

- Handles air and fluid without damaging cavitation

- Low Shear

- Ability to pump thick, viscous fluids

- Steady, measured flow at constant pressure

- Can run dry

- Handles abrasives well

- ATEX Zone 2 Category 3 Rating

- Rapid Delivery

- Only a 3 feet NPSHR usually

The nomenclature below describes the standard pump frame size, capacity, pressure capability, drive shaft arrangement, application and the serial number.

Other options are available. Most common are listed below.

Example: The pump series described above is a large rotary pump with rated capacity of 266 gallons per 100 revolutions. The pump is for high pressure application with a bottom drive shaft, pumping an extremely abrasive material. This pump also features: LARS.D.EN.F Cartridge Seals, Regular Drain Plugs, ANSI Standard Steel Transition Fittings, AGI 600 Housing Segments, NBR Orings, AR500 Wear Plates, NBR 70 Coated 4 Wing Helix Lobes. The pump serial number is 123456.

Example: The pump series described above is a large rotary pump with rated capacity of 266 gallons per 100 revolutions. The pump is for high pressure application with a bottom drive shaft, pumping an extremely abrasive material. This pump also features: LARS.D.EN.F Cartridge Seals, Regular Drain Plugs, ANSI Standard Steel Transition Fittings, AGI 600 Housing Segments, NBR Orings, AR500 Wear Plates, NBR 70 Coated 4 Wing Helix Lobes. The pump serial number is 123456.

Example: The pump series described above is a large rotary pump with rated capacity of 266 gallons per 100 revolutions. The pump is for high pressure application with a bottom drive shaft, pumping an extremely abrasive material. This pump also features: LARS.D.EN.F Cartridge Seals, Regular Drain Plugs, ANSI Standard Steel Transition Fittings, AGI 600 Housing Segments, NBR Orings, AR500 Wear Plates, NBR 70 Coated 4 Wing Helix Lobes. The pump serial number is 123456.

Example: The pump series described above is a large rotary pump with rated capacity of 266 gallons per 100 revolutions. The pump is for high pressure application with a bottom drive shaft, pumping an extremely abrasive material. This pump also features: LARS.D.EN.F Cartridge Seals, Regular Drain Plugs, ANSI Standard Steel Transition Fittings, AGI 600 Housing Segments, NBR Orings, AR500 Wear Plates, NBR 70 Coated 4 Wing Helix Lobes. The pump serial number is 123456.